Table of Contents

Most cars and trucks on the road today have an OBD2-compliant computer system. These On-Board Diagnostic Version 2 systems manage engine functions and diagnose problems. Along with the onboard computers, the OBDII standard provides universal troubleshooting equipment and procedures that help the do-it-yourself enthusiast and the professional mechanic quickly fix vehicle problems and get back on the road as soon as possible.

What Is OBD2?

Electronic diagnostic tools are nothing new. Our vehicles had them since Volkswagen introduced the first self-diagnostic system back in 1969. These systems improved vehicle maintained overnight by giving technicians the information they need to know what is happening inside the engine without taking it apart. However, these early systems were proprietary and very specific to their manufacturers.

In 1991, California established the first OBD standard to reduce exhaust emissions. The Environmental Protection Agency (EPA) expanded and brought it nationwide five years later as the OBD2 standard we have today. Because of this, every vehicle made after 1996 is guaranteed to be OBD-II compliant.

What Does OBD2 Do?

OBD2 provides a complete framework for control the entire engine electronically. It also provides a universal way to monitor and diagnose problems with the vehicle’s chassis, body, and accessory devices.

The OBD2 computer also controls the “Check Engine Light”, or Malfunction Indicator Light (MIL) as it is known in the industry. Because of this, the MIL is how most people interact with the system.

Finally, the OBDII computer saves a snapshot, called a freeze-frame, of the engine’s operating environment. A freeze-frame is all you need to diagnose and troubleshoot your vehicle.

You can even use OBD2 to customize the vehicle’s speed and performance through power loaders

Why Do We Need OBD-II Technology?

The OBD2 standard comes from a half-century attempt to deal with smog and other health problems in cities around the country. Before the standard, each manufacturer developed their own proprietary ways to do this. There was no real standard at the time, and getting compatible equipment for a vehicle was a lesson in frustration.

Now, you can diagnose and troubleshoot emission problems on any vehicle without worrying if you have the correct parts. OBD2 even goes beyond emissions to help you find and repair any problem under the hood from a single point of contact.

The OBD2 Diagnostic Connector

During their first attempt to establish a universal emissions system standard, the EPA asked the Society of Automobile Engineers to device a universal port. Their solution became the SAE J196 interface port we use today. This port, called the OBD2 Diagnostic Connector, is your main interface to your vehicle’s OBD-II system.

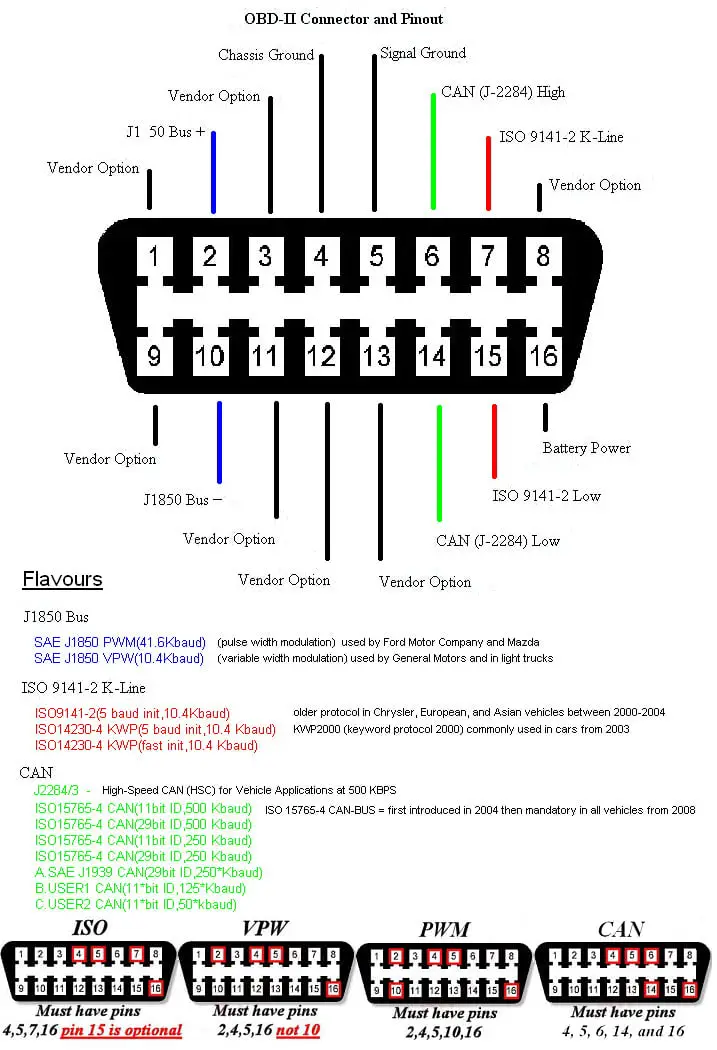

The Connector is a 16-pin, electronic interface that features two rows of eight female pins and a groove between them. The D-shaped port comes in two variations. Type A has the groove running its entire length and can handle 12-volt systems. Type B can easily do 24 vols with its spit grove.

Despite having room for 16 pins, your connector may only have a few of them available. These differences come from the OBDII transmission protocol it uses.

OBD2 Protocols

Credit: www.mbcluster.com

These OBD2 protocols came from a need to get information out of complaint systems while giving manufacturers time to something more universal. Because of this, the EPA and industry leaders created five different OBD2 protocols by the manufacturer.

SAE J1850 Variable Pulse Width

General Motors used variable pulse width modulation to transmit the data along Pin 2 as a 10.4-kps sequence of alternating high and low voltages.

SAE J1850 Pulse Width Modulation (KWP)

Ford preferred pulse width modulation (PWM). PWN is a more robust transmissions system, but it uses pulse length to define its bits. Because of this, it required a separate clock signal on Pin 10 along with the data on Pin 2. At least, it gave Ford a 41.6 kbps signal.

ISO 9141-2

Chrysler, as well as European and Asian manufacturers, had their own standard. This asynchronous serial connection worked like old computer serial ports. It transmits data as a single bit, but it allowed an upload and a download signal. OBD2 assigns these signals to pins 7 (K) and 15 (L) with a 10.4 kbps transfer rate. It was replaced with KWP2000 in 2004.

ISO 14230 Keyword Protocol (KWP) 2000

As the enhanced version of ISO 9141-2, KWP served as Chrysler’s bridge between the older format and CAN. It used the same asynchronous serial signal with similar bandwidth ratings. It did have a slow (5 baud) and fast variants based on how the initiate transfers.

ISO 15765-4/SAE J2480 Controller Area Network (CAN)

CAN is the true universal OBD2 protocol, used on every vehicle since 2008. Similar to the USB computer standard, CAM provides an industry-wide, message-based protocol that can run host free. It uses pins 6 and 14 as a two-wire, differential serial format that can clock transmission speed up to 1 Mbps. It can even handle communication between several subsystems at the same time, allowing carmakers to add additional functionality to the whole system.

Some manufacturers may include subsystems that are not OBD2-compliant, but you can rest assured that your 2008 or newer vehicle is at least CAN-certified.

Bonus: Which OBD2 Protocol is Supported by My Vehicle?

ODB2 Codes and OBD2 PIDs

To help facilitate communication, the OBD2 standard defines a list of standard diagnostic trouble codes (DTC). The DTC lets you quickly assess the health of an engine. You need a compliant scanner to get them, but they are easy to understand.

Most scan tools will attempt to interpret the code for you, but this handy chart will give you an insight into the most common OBD-II codes.

| DTC | Meaning/ Interpretation. |

| Absolute map | This is a live reading of the vehicle. Use it to look for similar conditions. |

|

PO 420 errors | An automatic self-test. These deliberate faults happen twice a month. |

| Load PCT 92.2 | The air entering the engine is below 100% |

| RPM | The RPM of the engine at the time of recording. |

| Upstream O2S Volts | Live performance reading of the oxygen sensor |

| Fuel SYS 2 N/A | No fuel injectors in the bank 2 |

| Fuel system good trip counter | Trip counter that turns off the MIL for the fuel DTC systems. |

| ECT (F) 221 | Engine temperature. |

| Test is done this trip | Monitor already ran and completed during the current trip. |

| VSS MPH | Vehicle engine speed when the data was recorded |

| Fuel SYS 1 CL | Fuel injection bank is in closed loops. |

OBD2 Parameter IDs

Along with the DTC, the OBD2 standard defines parameter IDs (PIDS). While the DTC transmit information out of the system, PIDs sends requests to it. Effectively they are the command codes for the system.

There are too many to list, but you can read more about them here.

10 OBD2 Service Modes

You will find both EPA-defined and manufacturer-specific PIDS, split into the following categories or service modes.

| Service (hex) | Description |

| 01 | To show you the current data |

| 02 | To show you the freeze frame data |

| 03 | To show you the stored Diagnostic Trouble Codes |

| 04 | To clear the Diagnostic Trouble Codes and stored values |

| 05 | To test the results, oxygen sensor monitoring (non-CAN only) |

| 06 | To test the results, other components/system monitoring (for CAN only) |

| 07 | To show you the pending DTCs (detected from the most recent driving cycle, meaning current or last trip) |

| 08 | To control the operation of the onboard component or system |

| 09 | To request some vehicle information |

| 0A | To permanently Diagnostic Trouble Codes (DTCs) (Cleared DTCs) |

OBD2 Applications

Originally, you need a dedicated OBDII scan tool to read the DTC, send PIDs, and interact with the subsystem. Today, you can use any electronic device to actually read the codes. That includes traditional scanners, a desktop or laptop computer, or your mobile device.

OBD2 Cable Scan Tools

Traditional cable scan tools are portable, hand-held devices you connect directly to the Diagnostic Connector. You will find a large variety of OBD2 scan tools on the market. Each has its own purpose, and therefore will only show a subset of all the features available to you.

Therefore, you generally want a scan tool that can read several protocols to give you as much information about your vehicle as you can afford. That way, you can use the same tool regardless if you decide to keep or trade your car in for another.

Either way, cable scan tools just provide a single menu-based display to read codes and descriptions. Some tools will even provide some vehicle-specific info as well.

Bluetooth OBD2 Scanners

Besides the wired scanners, you will see several wireless options. These OBD2 tools use Bluetooth adapters to retrieve data. These scan tools may even provide mobile-like reading and programming apps. Some may let you transmit the data to your phone or mobile device.

Many Bluetooth ODB-II apps with extra features you will never find on a traditional tool, including extensive logging solutions.

PC-based OBD2 Software

PCs offer several advantages over the dedicated handheld scan tools. OBD2 PC software offers larger displays. They provide immediate access to internet search tools.

You also have access to numerous full-featured, free and paid OBD2 diagnostic software. Many even let you customize the interface to suit your needs. Some ODB2 PC software can even offer video tutorials that can help you troubleshoot even the worse problems for no extra cost.

You also need PC-based OBD2 software to use data loggers.

Data Loggers

Perfect for prototypes and extensive testing, OBD2 data loggers provide time-stamped archives of your vehicle’s freeze frames. You must preprogram them to work, but they offer a simple solution if you want to record the data and not process it right away.

Emission testing

As the OBD2 standard exists to reduce emissions, it makes sense that there are dedicat4ed emissions testing modes for it. These tests are also much easier and quicker than the traditional tailpipe testing procedures, reducing the testing time down to seconds.

OBDII sensors can even find emissions problems that would otherwise go unnoticed with a tailpipe test.

Driver’s supplementary vehicle instrumentation

Some manufacturers provide additional vehicle information directly on the dashboard as an incentive to buy their vehicles. These dashboard apps are OBD2 scan tools build straight into the car you can use during normal operations.

You can even install these tools as aftermarket additions to the vehicle such as manifold vacuum, battery current, and other diagnostic monitors.

Does My Car Have OBD2?

If your vehicle comes from 1996 or newer, it has OBD2. Beyond that, you may find the system in cars as far back as 1994.

Most of the time, the only thing you must worry about is the transmission protocol. Before 2008, Manufacturers had their own proffered methods. So, you must check which protocol you have if you have a 2007 or older vehicle.

Fortunately, you just need to check the pins in the connector to answer the question. Each protocol has its own pin requirements, making it an easy check.

| Protocol | Pin 2 | Pin 4 | Pin 5 | Pin 6 | Pin 7 | Pin 10 | Pin 14 | Pin 15 | Pin 16 |

| SAE J1850 VPW | X | X | X | X | |||||

| SAE J1850 PWM | X | X | X | X | X | ||||

| ISO 9141-2 | X | X | X | X | X | ||||

| ISO 14230 KWP2000 |

| X | X |

| X |

|

| X | X |

|

ISO 15765-4 SAE J2480 (CAN) | X | X | X | X | X |

If your vehicle is 2008 or newer, your vehicle is guaranteed to be OBD2 CAM

compliant.

The Bottom Line

Since 1996, the OBD2 standard streamlined how we diagnose and troubleshoot problems with our vehicles. It defines a whole ecosystem of devices and subsystems that interact with each other so we can get more out of our rides. If you need more information on how it works with your vehicle, you can contact our representatives, and we will walk you through it so you can get the right tool for the job.

Read more: OBD1 vs OBD2: Definite Interpretation and Comparison